Metering Pump and Intelligent Control Panel for Odorizers

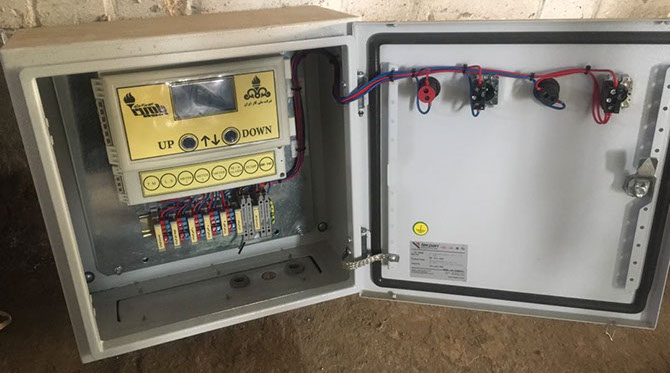

BMP Control Panel

BMP Metering Pump and Smart Control Panel

BMP Smart Control Panel- Analouge

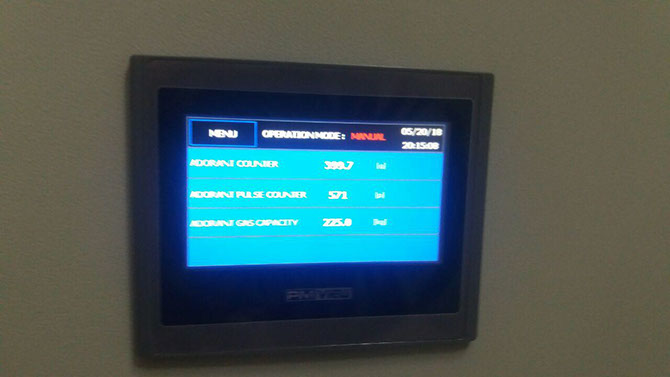

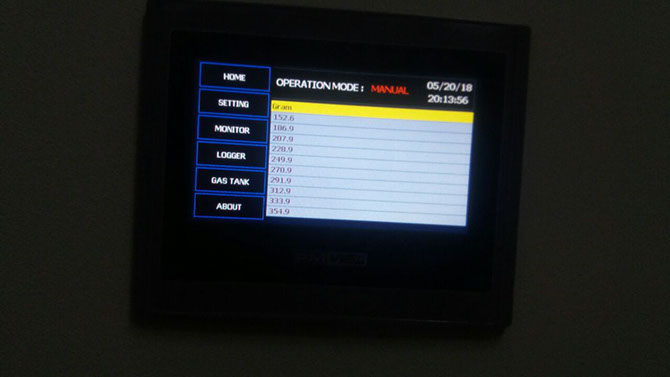

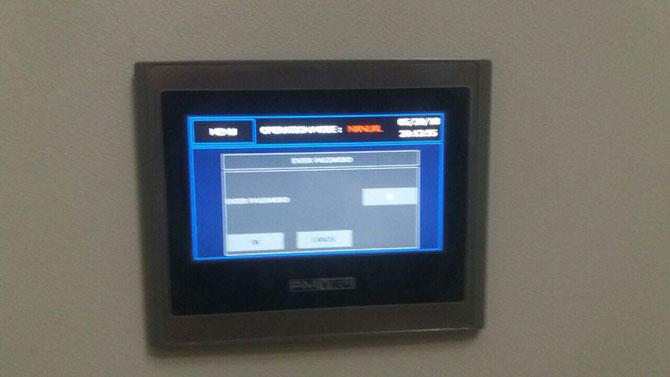

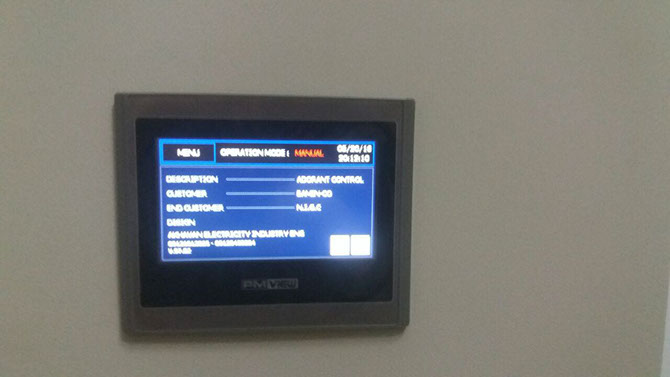

BMP Smart Control Panel- Digital

BMP Smart Control Panel-Analouge

BMP METERING PUMP

BMP METERING PUMP

BMP Smart Control Panel- Digital

BMP Smart Control Panel- Digital

BMP Smart Control Panel- Digital

BMP Smart Control Panel- Digital

BMP Smart Control Panel- Digital

BMP METERING PUMP7

12 - 13

<

>